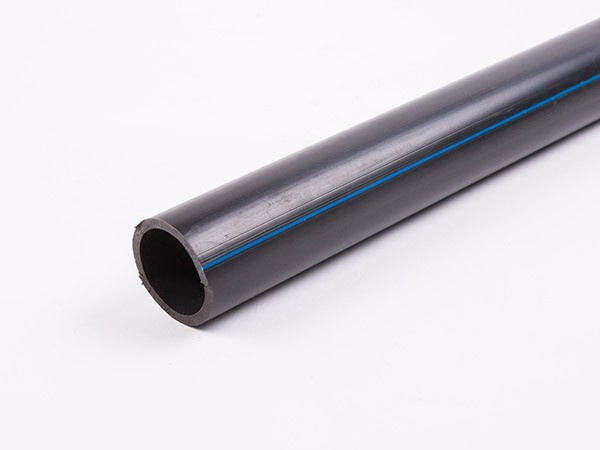

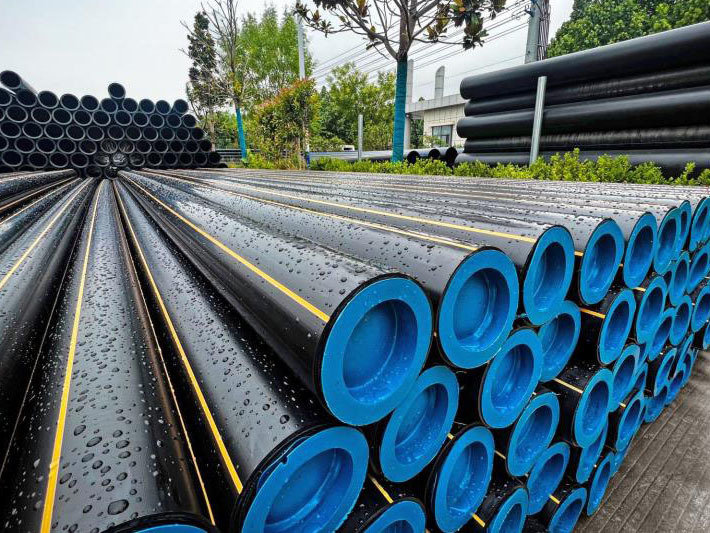

Product display

PE water supply pipe-PE pipe price

High-quality pe pipe: the inner and outer surfaces of the pipe are smooth and smooth without defects such as bubbles, depressions and impurities. Inferior PE pipe: the inner and outer surfaces of the pipe are not smooth, not bright, pitted, and the inner and outer surfaces have obvious depressions.

Classification:

PE water supply pipe

Key words:

Hotline:

Product Description

1. look at the appearance

high-quality pe pipe: the inner and outer surfaces of the pipe are smooth and smooth without defects such as bubbles, depressions and impurities.

Inferior PE pipe: the inner and outer surfaces of the pipe are not smooth, not bright, pitted, and the inner and outer surfaces have obvious depressions.

2. Milling Strip

High quality pe pipeline: oil bright, smooth, repeated folding is not easy to break.

Inferior PE pipe: dark color, folding easy to break.

3. welding port

The qualified weld joint shall have smooth and symmetrical flanging along the whole circumference of the pipe, and the low depth of the flanging shall not be lower than the pipe surface; the misalignment at any place on the outer circumference adjacent to the flanging on both sides of the weld shall not exceed 10% of the pipe wall thickness;

High quality PE pipe: flanging smooth and flat. After the joint pressure, the flanging can be longer.

Inferior PE pipe: a large number of pores are produced on the surface after flanging. The flanging is short after the joint pressure.

4. sense of smell

High-quality PE pipe: The product just processed or heated and melted has a slight plastic fragrance, and the cooled product has no peculiar smell.

Inferior PE pipe: a pungent smell.

5. elongation at break

Elongation at break refers to the ratio of the length of the sample to the original length. The higher the elongation at break, the better the flexibility and performance of the product.

High quality PE pipe: stretched to 3.5 times without breaking.

Inferior PE pipe: elongated easy to break, poor toughness.

6. oxidation induction time

Oxidation induction time is the time when the autocatalytic oxidation reaction of the sample starts under the condition of high temperature oxygen, and it is an index to evaluate the thermal degradation resistance of the material in molding, storage, welding and use. The longer the oxidation induction time, the better the aging resistance and the better the performance of the product.

Previous Page

Next Page

Previous Page

Next Page

Product inquiry